Audit of Occupational Health and Safety

Date: February 2015

PDF Version (268 Kb, 29 Pages)

Table of Contents

List of Acronyms

| AANDC |

Aboriginal Affairs and Northern Development Canada |

|---|---|

| ADM |

Assistant Deputy Minister |

| CLC Part II |

Canada Labour Code, Part II |

| HPP |

Hazard Prevention Program |

| HRWSB |

Human Resources and Workplace Services Branch |

| NJC |

National Joint Council |

| NPHSC |

National Policy Health and Safety Committee |

| OHS |

Occupational Health and Safety |

| SOHSD |

Security and Occupational Health and Safety Division |

| TB |

Treasury Board |

Executive Summary

Background

Aboriginal Affairs and Northern Development Canada (AANDC or "the Department") is one of the federal government departments responsible for meeting the Government of Canada's obligations and commitments to First Nations, Inuit and Métis, and for fulfilling the federal government's constitutional responsibilities in the North. The Department is divided into nine sectors and ten regions, and has a diverse workforce that spans across the nation. The business operations include a variety of occupations, some of which involve exposure to various hazards.

This report presents the findings of the AANDC Audit of Occupational Health and Safety. The decision to conduct the audit was identified in the Department's 2014-2015 to 2016-2017 Risk-Based Audit Plan and approved by the Deputy Minister on February 6, 2014. The audit focused on Occupational Health and Safety (OHS) management practices at AANDC'S Headquarters and included three regional site visits to Ontario, Alberta, and Nunavut. AANDC must adhere to federal OHS legislation, including the Canada Labour Code, Part II, and the Canada Occupational Health and Safety Regulations. Treasury Board (TB) has also established a Policy on Occupational Health and Safety and an Occupational Health and Safety Directive. The TB OHS Directive aims to complement the OHS programs found in federal departments and agencies and includes very specific safety and hazard prevention requirements. Both the CLC Part II and the TB Directive are intended as minimum standards that should be complemented by an employer's own OHS policies and procedures.

Audit Objective and Scope

The objective of the audit was to provide assurance on the adequacy and effectiveness of the system of management controls in place to support AANDC's OHS program and to ensure compliance with relevant legislation, regulations and policies. The audit did not seek to obtain assurance that employees consistently work in a safe manner or that workplaces are free of unreasonable hazards; however, point-in-time observations were made of workplaces and work practices in the regions selected for examination.

The audit scope included key elements of AANDC's OHS management control framework, including OHS governance, roles and responsibilities, OHS objective and priority setting, planning, risk-based hazard prevention, OHS committee operations, and the OHS-related activities of OHS professionals, managers, supervisors and employees. The audit focused on OHS management practices at AANDC's Headquarters and within the regions of Ontario, Alberta and Nunavut for the period April 2012 to September 2014. The audit did not examine federally regulated activities and operations regarding management liability for OHS incidents within First Nation communities.

Statement of Conformance

The audit conforms to the Internal Auditing Standards for the Government of Canada, as supported by the results of the quality assurance and improvement program.

Observations

In response to AANDC's 2009 Audit of Occupational Health and Safety, AANDC has made improvements in its OHS program. The Department has developed a comprehensive OHS Program Manual, describing OHS roles and responsibilities; increased its capacity through the addition of dedicated OHS personnel; and improved the operations of local OHS committees. These changes have led to improvements in the Department's conformance to OHS regulatory and policy requirements in some regions.

Notwithstanding improvements made to the OHS program in recent years, opportunities for improvement exist at the national level and in all regions visited. There is limited measurement of OHS program performance in regions and nationally, limited formal reporting to management on OHS program effectiveness and very little monitoring of OHS program implementation. While a very limited number of workplaces and programs (e.g., Northern Contaminated Sites Program) have implemented risk-based OHS hazard prevention programs, there is a general lack of occupational hazard identification and assessment, few hazard prevention programs and very little hazard-specific training. Improving these practices will further strengthen AANDC's OHS program, improve the organization's safety culture, and help to reduce safety incidents.

Conclusion

The audit found that the AANDC OHS program is partially effective with some opportunities for improvement. While the AANDC OHS program and capacity of the OHS organization have improved since the 2009 Audit of OHS, continued improvements are required in the areas of OHS priority setting and planning, hazard-focused OHS training, hazard-focused preventive measures, compliance of local and national OHS committees to legislative and regulatory requirements, and OHS program monitoring and reporting.

Recommendations

The audit team identified areas where management control practices and processes could be improved, resulting in the following four recommendations:

- The Director General, Human Resources and Workplace Services Branch, with the support of the National Policy Health and Safety Committee, should ensure that a comprehensive National Occupational Health and Safety (OHS) Plan, based on the results of a completed departmental hazard assessment, is developed and implemented. In addition, the Senior Assistant Deputy Minister, Regional Operations, and the Assistant Deputy Minister, Northern Affairs Organization, should ensure that all regions develop and implement regional OHS plans that: i) address national OHS priorities and ii) establish region-specific priorities aimed at regional hazards.

- The Director General, Human Resources and Workplace Services Branch, should ensure that a departmental Occupational Health and Safety (OHS) performance dashboard that tracks progress against key performance indicators (leading and lagging) and national OHS program priorities is developed. This information should be reported to senior management and the National Policy Health and Safety Committee at regular intervals to inform their oversight of the OHS program. Further, OHS performance dashboards and region-specific program deficiencies should be reported to Regional Directors General and Workplace OHS Committees at least annually.

- The Director General, Human Resources and Workplace Services Branch, should ensure that a program is put in place for all managers and supervisors with responsibility for employees exposed to occupational and workplace hazards receive training on developing, implementing and maintaining hazard prevention programs. Further, the DG HRWSB should perform periodic reviews of the implementation of hazard prevention programs and highlight deficiencies to departmental senior management and the National Policy Health and Safety Committee as well as to responsible Assistant Deputy Ministers and/or Regional Directors General.

- The Director General, Human Resources and Workplace Services Branch, should ensure that all Assistant Deputy Ministers and internal services branch heads develop and implement hazard prevention programs for their respective areas, including formal identification and assessment of workplace hazards, formal safety training programs, and preventive and protective safety measures. Workplaces and occupations with the greatest exposure to hazards should receive immediate attention.

Management Response

Management is in agreement with the findings, has accepted the recommendations included in the report, and has developed a management action plan to address them. The management action plan has been integrated in this report.

1. Background

Aboriginal Affairs and Northern Development Canada (AANDC or "the Department") included the Audit of Occupational Health and Safety (OHS) in its 2014-2015 to 2016-2017 Risk-Based Audit Plan, approved by the Deputy Minister on February 6, 2014. The audit was identified as a high priority due to the requirement for departments to have controls in place that help ensure compliance with the OHS requirements contained in the Canada Labour Code (CLC), Part II and its regulations, and with Treasury Board OHS policies, directives and standards.

1.1 OHS Regulatory and Policy Context

The governance of OHS at AANDC occurs within a complex legislative, regulatory and policy framework. It is the policy of the federal government to provide employees with a safe and healthy working environment. The CLC Part II outlines the legislative framework and the duties and responsibilities of the employer and employees pertaining to OHS. Each duty outlined in the CLC Part II has a corresponding regulation prescribing specific requirements. As an employer, AANDC must adhere to this OHS legislation.

Treasury Board (TB) has a Policy on OHS and, in collaboration with bargaining agents and public service employers, established the National Joint Council OHS Directive. The OHS Directive aims to complement the OHS programs established in federal departments and agencies and includes very specific safety and hazard prevention requirements. Both the CLC Part II and the TB/NJC OHS Directive are intended as minimum standards that should be expanded on by a department's or agency's specific OHS policies and procedures. Per the TB Policy on OHS, federal departments and agencies must implement the requirements of the CLC Part II, maintain effective OHS programs, and provide training and information to employees. The elements of the TB/NJC OHS Directive are included in Exhibit 1 below.

Exhibit 1:

OHS Policies/Directives Established by Treasury Board and the National Joint Council

- Part I – General

- Part II – Permanent Structures and Safe Occupancy of the Workplace

- Part III – Elevated Work Structures

- Part IV –Elevated Devices

- Part V – Boilers and Pressure Vessels

- Part VI – Lighting

- Part VII – Noise Control (Level of Sounds)

- Part VIII – Electrical Safety

- Part IX – Sanitation

- Part X – Pesticides

- Part XI – Hazardous Substances

- Part XII – Confined Spaces

- Part XIII – Personal and Protective Equipment and Clothing

- Part XIV – Tools and Machinery

- Part XV – Materials Handling

- Part XVI – Motor Vehicle Operations

- Part XVII – Hazardous Occurrence Investigation, Recording and Reporting

- Part XVIII – First Aid

- Part XIX – Refusal to Work

- Part XX – Occupational Health and Safety Committees and Representatives

Taken together, this regulatory and policy framework prescribes, in detail, specific requirements relating to OHS program development and implementation, administrative practices, roles and responsibilities, conditions of workplaces and equipment, safety practices and methods, hazard controls, monitoring, and evaluation, among other elementsFootnote 1. In addition, the Criminal Code of Canada makes it an offence to act or fail to act in ways that result in negligent harm to employees, guest workers, contract workers and the general public.Footnote 2

1.2 AANDC's System of OHS Management Controls

OHS Governance and Policy

AANDC's OHS Program Manual, consisting of eight chapters, outlines the Department's OHS policies, guidelines, and legal requirements, including those set forth in the CLC Part II and its associated regulations, the Criminal Code of Canada, as well as the TB OHS Policy and Directive. AANDC has continued to make updates to the OHS Program Manual, most recently updated in July 2014, in which the OHS policies, programs and procedures set minimum standards for the implementation of OHS across the Department.

The OHS Program Manual describes the OHS roles and responsibilities assigned to all departmental officials, including managers, supervisors, employees, health and safety representatives and workplace OHS committee members. The intent of the OHS Program Manual is to provide guidance to employees in the performance of activities that will ensure compliance and protection of personnel in the context of health and safety. A list of the policies contained within the AANDC OHS Program Manual is shown in Exhibit 2 below.

Exhibit 2:

Contents of AANDC Occupational Health and Safety Program Manual

- Chapter 1 – Commitment and Accountability

- Chapter 2 – Risk Control

- Chapter 3 – Occupational Health and Safety Training and Education

- Chapter 4 – Hazardous Occurrences and Compensation of Workplace Accidents

- Chapter 5 – A Safe Workplace

- Chapter 6 – Committees and Health and Safety Representatives

- Chapter 7 – Inspections and Audits

- Chapter 8 – Internal Complaint Resolution and Work Refusal

AANDC's OHS Organization

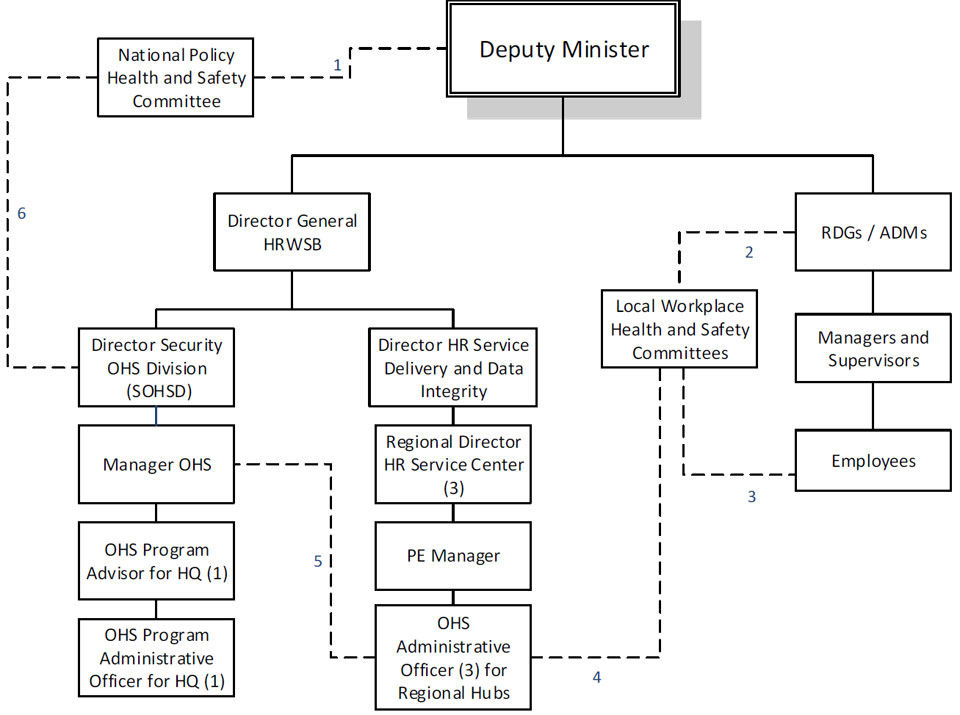

The structure of the OHS organization at AANDC is composed of key groups, including the National Policy Health and Safety Committee (NPHSC), the Headquarters Security and OHS Division (SOHSD), three regional Human Resources (HR) Service Centres, Workplace OHS Committees, and OHS Representatives. A depiction of AANDC's OHS organizational chart is depicted in Exhibit 3 below.

Exhibit 3: AANDC OHS Organizational Structure

Text alternative for Exhibit 3: AANDC OHS Organizational Structure

Exhibit 3 illustrates the OHS organizational structure at AANDC. At the highest level of AANDC’s OHS Organizational Structure is the Deputy Minister, who oversees direct reporting from the Director General, HRWSB and RDGs/ADMs. Under the umbrella of the Director General, the HRWSB includes the Director of Security OHS Division (SOHSD) and the Director of HR Service Delivery and Data Integrity. The RDGs/ADMs oversee direct reporting from their Managers and Supervisors, who have a direct reporting relationship with their employees.

The Director of SOHSD receives direct reporting from the Manager of OHS while the OHS Program Advisor of HQ and OHS Administrative Officer for HQ report to the Manager of OHS. At an organizational level, SOHSD supports the activities of the National Policy Health and Safety Committee (NPHSC), which escalates matters to the Deputy Minister as required.

The Director of HR Service Delivery and Data Integrity has a direct reporting relationship with the Regional Director HR Service Centre, whose subordinates are the PE Manager and OHS Administrative Officers for Regional Hubs.

From a functional perspective, at a regional/local level, employees report OHS issues and concerns to their local workplace OHS committee. Regional OHS Administrative Officers collect information regarding meetings/inspections/injuries from local workplace OHS Committees and communicate the information/reports to the Manager of OHS at HQ. Local workplace OHS committees also provide regular reporting to their senior management.

The diagram also depicts the direct and functional inter-relationship between each level, identified as 1 to 6 on the exhibit.

The following are the functional relationships:

- #1: between Deputy Minister and NPHSC;

- #2: between RDGs/ADMs and Local Workplace Health and Safety Committees;

- #3: between Employees and Local Workplace Health and Safety Committees;

- #4: between Local Workplace Health and Safety Committees and OHS Administrative Officers;

- #5: between OHS Administrative Officers and Manager OHS; and,

- #6: between Director SOHSD and NPHSC.

- - Dashed Line: Indicates Functional Relationship

- The NPHSC reports to the Deputy Minister and escalates OHS issues where necessary

- Local workplace OHS committees provide regular reporting to senior management. For HQ-based ADMs and DGs, only two have local workplace OHS committees reporting to them because committees are attached to physical locations and not organizational structure

- Employees report OHS issues and concerns to their local workplace OHS committee

- Regional OHS Administrative Officers collect information regarding meetings/inspections/injuries from local workplace OHS Committees

- Manager OHS at HQ collects information and communicates with regional OHS Administrative Officers

- The SOHSD supports the activities of the NPHSC, and the NPHSC escalates matters to the DM as required

As part of the Department's implementation of the Deficit Reduction Action Plan (DRAP), announced in the 2012 Federal Budget, regional human resource functions previously located in the ten regional offices were consolidated into three regional Human Resource (HR) Service Centres. These HR Service Centres are located in Edmonton (servicing the British Columbia, Alberta, Saskatchewan and Yukon regions), Toronto (servicing the Manitoba, Ontario and Northwest Territories regions), and Québec City (servicing the Québec, Nunavut and Atlantic regions). The regional HR Service Centres provide advice, guidance, and support regarding regional OHS matters to managers, employees, OHS Committee members and OHS representatives. As a result of DRAP, AANDC has introduced three full-time OHS Administrative Officer (AS-03) positions, one in each of the three HR Service Centres. The role of these OHS Administrative Officers is to provide support for the implementation of the OHS program.

The operations of the OHS program are largely decentralized, where the management and implementation of the program is delegated to regional offices with some support from the SOHSD and the OHS Administrative Officers in the HR Service Centres. The SOHSD provides functional direction, information and advice on national legislation, administrative and health matters to management, employees, HR Service Centres and OHS Administrative Officers. In keeping with the AANDC OHS Policy requirements senior management assumes the responsibility for ensuring the development, implementation, and monitoring of the OHS program at all departmental workplaces. Ultimately, Regional Directors General and Sector Assistant Deputy Ministers are accountable for managing and overseeing OHS programs within their respective areas.

AANDC has established the NPHSC in accordance with the requirements of the CLC Part II and the TB/NJC OHS Directive. The NPHSC's mandate is to provide national leadership, strategic direction and support to regional and local committees, and serves as the national forum for union/management consultation and problem solving for health and safety in the workplace.

The NPHSC participates with management in the development and monitoring of health and safety programs established by the Department to ensure compliance with the governing legislation and ensures employees are fully aware of and understand OHS. NPHSC addresses issues that have a department-wide impact, including the development, review and oversight of policies and programs, work process, and procedures. The OHS Manager, within the SOHSD, liaises between OHS Administrative Officers and the NPHSC in the monitoring and implementation of the OHS program.

The establishment of local Workplace OHS Committees is outlined in the Commitment and Accountability chapter of the OHS Program Manual. AANDC has established a number of Workplace Health and Safety Committees in compliance with the CLC Part II, which requires a local committee in each workplace with 20 or more workers. Employees sitting on OHS committees are required to receive training and allotted time for participation in meetings and carrying out their duties. For workplaces with less than 20 employees, an OHS Representative (an employee that does not exercise managerial functions) must be appointed in lieu of establishing a local OHS committee.

2009 Audit of OHS

The previous AANDC Audit of OHS, conducted in 2009, identified 10 recommendations, including the development of a national OHS training program, the need for additional dedicated OHS capacity, and the need to address the lack of OHS policy and procedures, among others. Section 5.3 of this report, Follow-up on 2009 Audit of Occupational Health and Safety, provides a list of the 2009 audit recommendations as well as an assessment of management's progress in addressing these recommendations.

2. Audit Objective and Scope

2.1 Audit Objective

The objective of the audit was to provide assurance on the adequacy and effectiveness of the system of management controls in place to support AANDC’s OHS program and to ensure compliance with relevant legislation, regulations and policies. The audit did not seek to obtain assurance that employees consistently work in a safe manner and that workplaces are free of unreasonable hazards; however, point-in-time observations were made of workplaces and work practices in the regions selected for examination.2.2 Audit Scope

The audit examined key elements of AANDC’s system of OHS management controls, including:

- Design of OHS governance processes and appropriateness of OHS-related roles and responsibilities;

- Adequacy of OHS objective setting, priority setting and planning activities;

- Appropriateness of risk-based hazard prevention programs put in place for higher-risk occupations and workplaces;

- Adequacy of supports made available to OHS committee members, OHS professionals, managers, supervisors and employees to enable them to fulfill their OHS roles and responsibilities;

- Effectiveness of the national and regional OHS committees, including compliance to related legislative and regulatory requirements;

- Adequacy of controls for monitoring and measuring OHS program implementation; and,

- Improvements made to the OHS program as a result of the 2009 internal audit.

The audit focused on OHS management practices at Headquarters and within the regions of Ontario, Alberta and Nunavut for the period April 1, 2012 to September 30, 2014. The audit work conducted in the Ontario and Alberta regions included an examination of three federally operated schools, two in Ontario and one in Alberta. The audit also examined compliance with the CLC Part II and AANDC’s OHS program requirements. The audit did not examine federally regulated activities and operations regarding management liability for OHS incidents within First Nation communities.

3. Approach and Methodology

The audit was planned and conducted in accordance with the requirements of the TB Policy on Internal Audit and followed the Internal Auditing Standards for the Government of Canada. The audit team examined sufficient, reliable and relevant evidence to provide a reasonable level of assurance in support of the audit conclusion. The principal audit techniques used included:

- Reviews of OHS-related documentation obtained at Headquarters and at each region visited, including OHS policies, program documents, procedures, samples of hazardous occurrences or similar records, inspection records, OHS training records, OHS workplace committee minutes, NPHSC minutes, return to work records, employee training records, investigation reports, and hazard assessment and control records;

- Walkthrough tours and visual inspections of the workplaces visited for each region selected were performed. The walkthroughs were guided by detailed inspection checklists prepared to evaluate compliance with the audit criteria that pertain to health and safety conditions of the particular workplaces, equipment and materials contained therein, and the safety-related work practices of the personnel;

- Structured interviews conducted with AANDC SOHSD employees, NPHSC members, regional management, OHS administrative officers and a sample of regional employees in order to examine awareness, understanding, and existence of OHS processes, procedures and practices and to validate information obtained through document review and inspection; and,

- Tests performed to determine compliance with OHS legislation, regulations, and AANDC and TB OHS policies, directives and programs.

The approach used to address the audit objective included the development of audit criteria, against which observations and conclusions were drawn. Prior to finalizing the audit criteria, they were assessed for significance and areas of greatest risk. These audit criteria, presented in Appendix A, were formulated from requirements of the CLC Part II and its associated regulations, and the TB OHS Policy. The audit criteria were grouped into three categories that closely align to requirements of CLC Part II. These included:

- Commitment, leadership and participation;

- OHS planning and implementation; and,

- Monitoring and oversight.

4. Conclusion

The audit found that AANDC’s OHS program is partially effective with some opportunities for improvement. While the AANDC OHS program and capacity of the OHS organization have improved since the 2009 Audit of OHS, continued improvements are required in the areas of OHS priority setting and planning, hazard-focused OHS training, hazard-focused preventive measures, compliance of local and national OHS committees to legislative and regulatory requirements, and OHS program monitoring and reporting.

5. Findings and Recommendations

Based on the evidence gathered through documentation review, interviews, and analysis, each of the three lines of enquiry was assessed against pre-established audit criteria, as detailed in Appendix A. Where a difference between the audit criterion and the observed practice was found, the risk of the gap was evaluated and used to develop the conclusion and corresponding recommendations for improvement. This section provides the findings of the audit, with a focus on those areas where gaps were observed and recommendations for improvement were identified.

OHS5.1 Governance, Planning and Oversight

5.1.1 Commitment, Leadership and Employee Participation

Management commitment and leadership, and effective worker participation are crucial to the success of a sound OHS management program. This includes leadership over OHS activities and senior-level assumption of overall responsibility for the system of OHS management controls. It also includes the designation of one or more representatives of management who, irrespective of other responsibilities, have defined roles, responsibilities, and authority for ensuring that an OHS management system is established, maintained, and reviewed. All of this should be done in consultation with employees.

At AANDC, OHS operations are largely decentralized with some support from the Headquarters OHS Division (SOHSD) and OHS Administrative Officers in the regional Human Resource (HR) Service Centres. Ultimately, Regional Directors General and Assistant Deputy Ministers have responsibility for managing and overseeing OHS programs within their respective organizations.

The AANDC OHS Program Manual describes the OHS roles and responsibilities from the level of the Deputy Minister down to supervisors and employees. In the case of the Assistant Deputy Ministers, Regional Directors General and Directors General, the policy requires that they provide leadership in the effective implementation and monitoring of OHS within their areas of responsibility. For all regions examined, there were limited levels of regional senior management involvement in the OHS program, including program planning, OHS communications and awareness activities, and OHS program oversight. Further, in all regions examined, we observed that local OHS Committee members are assuming some of management's responsibilities for addressing gaps in the regional OHS programs. The CLC Part II and its associated regulations establish that workplace committees play a monitoring and advisory role; they are not mandated to support implementation of OHS programs and initiatives.

In all of the regions examined, managers interviewed described their involvement in Workplace OHS Committees as being largely reactive to issues and concerns brought forward by Committee members and staff. Our review of OHS documentation corroborated this. There is minimal proactive OHS planning that occurs at the regional and Workplace OHS Committee levels, and only one of the four Committees observed had an annual committee work plan.

It was observed that workplace OHS Committee members have generally assumed primary responsibility for addressing OHS issues and concerns that arise including those identified through workplace inspections and developing local worksite OHS procedures. Almost all Workplace OHS Committee employee representatives interviewed reported that OHS is an add-on to their existing full-time workload and that they felt they needed more time to fulfill their OHS Committee responsibilities.

A higher level of OHS program implementation was observed in regions where the OHS Administrative Officers are physically located. This extra layer of support for the Workplace OHS Committees has lessened the workload for committee members; however, the OHS Administrative Officer capacity does not allow them to assist on all areas of responsibility of the Workplace OHS Committee and OHS program. Of the three full-time OHS Administrative Officer positions in regional HR Service Centres, one is presently vacant (in the position at the Western-Yukon HR Service Centre). The OHS Program Advisor (AS-04) position within SOHSD is also presently vacant.

5.1.2 OHS Program Planning

In a well-functioning OHS program, a formal planning regime is in place to identify and prioritize OHS-related hazards, risks, legal requirements, and OHS program deficiencies. The CLC Part II reinforces that proper planning is a key element of an effective Hazard Prevention Program (HPP), which is discussed in more detail later in this report. The Canada Occupational Health and Safety Regulations further establish that an effective HPP should include an implementation plan, hazard identification and assessment methodology, hazard identification and assessment, preventive measures, employee education, and periodic review. An effective OHS planning process should include the establishment of appropriate objectives and targets, and cascading plans to achieve compliance with legal and policy requirements. Hazard and risk assessments are the foundation for OHS planning, ensuring that policies, preventive measures and training regimes are properly designed.

As outlined in AANDC's OHS Program Manual, the national OHS Manager within SOHSD is responsible, in consultation with the NPHSC, for administering the HPP. Managers throughout the Department are responsible for implementing hazard and risk-based preventive measures and training regimes.

Further, CLC Part II requires that AANDC develop, implement and monitor, in consultation with the NPHSCFootnote 3, a prescribed program for the prevention of hazards in the workplace appropriate to the size and nature of the hazards in it. Hazard identification and risk assessments were found to be inadequate in all regions visited, with only one out of three regions examined having completed formal hazard assessments for some of its operations.

OHS-related plans from the NPHSC, SOHSD, HR Service Centres, OHS Administrative Officers and Workplace OHS Committees from across the Department were examined where available. We found that they were not well aligned, incomplete and did not focus on areas of greatest risk. Measureable OHS targets and objectives were not established and most Workplace OHS Committees had little to no OHS plans in place. This inadequate planning is contributing to a fragmented implementation of the OHS program and duplication of efforts across the Department.

Recommendation

1. The Director General, Human Resources and Workplace Services Branch, with the support of the National Policy Health and Safety Committee, should ensure that a comprehensive National Occupational Health and Safety (OHS) Plan, based on the results of a completed departmental hazard assessment, is developed and implemented. In addition, the Senior Assistant Deputy Minister, Regional Operations, and the Assistant Deputy Minister, Northern Affairs Organization, should ensure that all regions develop and implement regional OHS plans that: i) address national OHS priorities and ii) establish region-specific priorities aimed at regional hazards.

5.1.3 Performance Reporting, Oversight and Continuous Improvement

In a well-functioning OHS program, management reviews the organization's OHS program at planned intervals to ensure its continuing suitability, adequacy and effectiveness. The objective of these formal and informal reviews is to identify any needed changes to the OHS program and opportunities for continued improvement. These requirements are embedded throughout the CLC Part II and its associated regulations.

AANDC's OHS Program Manual notes that the responsibility for monitoring the implementation of OHS programs is assigned to the Director General, Human Resources and Workplace Services Branch (HRWSB). Assistant Deputy Ministers, Regional Directors General and Directors General are required to implement and monitor OHS programs within their respective areas of responsibility, while Directors, Managers and supervisors are required to implement and ensure conformance with applicable OHS policies, directives, procedures and guidelines.

The audit identified inadequate measurement and reporting of OHS performance at all levels of the Department. The SOHSD is in the process of implementing a performance measurement regime, including tools to collect OHS performance data and processes to feed this information to Headquarters. The audit highlighted data integrity issues with the information reported by regions, and the OHS Administrative Officers are proactively working to resolve these issues. Examples of issues noted are: incomplete or lack of tracking of committee activities and meetings, lack of logs to track incidents, and incomplete tracking and documentation pertaining to work-related injuries.

The audit identified limited information on the effectiveness of regional OHS program implementation being made available to regional management and the NPHSC. Regional Directors General were not aware of important indicators of non-performance and non-compliance, as they are not receiving the necessary information. Examples of deviations which are not being elevated to regional senior management include, workplace OHS committees not meeting their legislative requirements to conduct meetings at required intervals, low levels of OHS training in some workplaces, failure to resolve OHS issues raised through committee meetings in a timely manner, and OHS inspections not being completed.

In the absence of performance information and routine reporting to management, we concluded that monitoring and oversight of the effectiveness of OHS program nationally and regionally, including compliance with legislation and policy requirements, was inadequate. The audit identified opportunities to strengthen OHS governance and communications in the Department, as highlighted in the diagram below.

Exhibit 4 : AANDC Occupational Health and Safety Organizational Structure

Text alternative for Exhibit 4 : AANDC Occupational Health and Safety Organizational Structure

This diagram also represents OHS organizational structure at AANDC. At the highest level of AANDC’s OHS Organizational Structure is the Deputy Minister, who oversees direct reporting from the Director General, HRWSB and RDGs/ADMs. Under the umbrella of the Director General, the HRWSB includes the Director of Security OHS Division (SOHSD) and the Director of HR Service Delivery and Data Integrity. The RDGs/ADMs oversee direct reporting from their Managers and Supervisors, who have a direct reporting relationship with their employees.

The Director of SOHSD receives direct reporting from the Manager of OHS while the OHS Program Advisor of HQ and OHS Administrative Officer for HQ report to the Manager of OHS. At an organizational level, SOHSD supports the activities of the National Policy Health and Safety Committee (NPHSC), which escalates matters to the Deputy Minister as required.

The Director of HR Service Delivery and Data Integrity has a direct reporting relationship with the Regional Director HR Service Centre, whose subordinates are the PE Manager and OHS Administrative Officers for Regional Hubs.

From a functional perspective, at a regional/local level, employees report OHS issues and concerns to their local workplace OHS committee. Regional OHS Administrative Officers collect information regarding meetings/inspections/injuries from local workplace OHS Committees and communicate the information/reports to the Manager of OHS at HQ. Local workplace OHS committees also provide regular reporting to their senior management.

The diagram also depicts the direct and functional inter-relationship between each level, identified as 1 to 6 on the exhibit.

The following are the functional relationships:

- #1: between Deputy Minister and NPHSC;

- #2: between RDGs/ADMs and Local Workplace Health and Safety Committees;

- #3: between Employees and Local Workplace Health and Safety Committees;

- #4: between Local Workplace Health and Safety Committees and OHS Administrative Officers;

- #5: between OHS Administrative Officers and Manager OHS; and,

- #6: between Director SOHSD and NPHSC.

This diagram also indicates where improved communication is required: i) between sectors/regional managers/supervisors and Local Workplace Health and Safety Committees ii) between Local Workplace Health and Safety Committees and Regional Hubs OHS administrative Officers iii) between regional OHS administrative officer and HQ OHS Manager, and, iv) between Director of the Security OHS Division and National Policy Health and Safety Committee.

Red Line: indicates where improved communication is required

- - Dashed Line: Indicates Functional Relationship

- The NPHSC reports to the Deputy Minister and escalates OHS issues where necessary

- Local workplace OHS Committees provide regular reporting to senior management. For HQ-based ADMs and DGs, only two have local workplace OHS Committees reporting to them as committees are attached to physical locations and not organizational structures

- Employees report OHS issues and concerns to their local workplace OHS committee

- Regional OHS Administrative Officers collect information on meetings/inspections/injuries from local workplace OHS Committees

- Manager OHS at HQ collects information and communicates with regional OHS Administrative Officers

- SOHSD supports the activities of the NPHSC, and the NPHSC escalates matters to the DM as required

Recommendation

2. The Director General, Human Resources and Workplace Services Branch, should ensure that a departmental Occupational Health and Safety (OHS) performance dashboard that tracks progress against key performance indicators (leading and lagging) and national OHS program priorities is developed. This information should be reported to senior management and the National Policy Health and Safety Committee at regular intervals to inform their oversight of the OHS program. Further, OHS performance dashboards and region-specific program deficiencies should be reported to Regional Directors General and Workplace OHS Committees at least annually.

5.2 Implementation of the OHS Program

Implementation of the OHS program includes determining, establishing, and maintaining the infrastructure and resources needed to achieve conformity with legislative and policy requirements and ensure the protection of workers. This includes:

- Establishing and maintaining processes to implement preventive and protective measures that address identified hazards and risks (i.e. Hazard Prevention Programs);

- Ensuring that supervisors and employees are aware, trained and competent to implement the OHS program; and

- Maintaining the documents and records necessary to effectively implement the OHS program and assess conformance with legislative and policy requirements.

5.2.1 Departmental OHS directives, procedures and standards

AANDC has developed an OHS Program Manual that includes numerous policy-level program requirements. This program provides specific OHS requirements and direction to managers in implementing the provisions of its standards to meet the CLC Part II and associated regulations (e.g., rolling out a Hazard Prevention Program, managing hazardous occurrences and requirements of the Workplace OHS Committees, etc). It is the responsibility of each region to implement the elements of the national policies.

5.2.2 Hazard Prevention Programs

As discussed above in Section 5.1.2 of this report, every Director, Manager and supervisor is accountable for implementing preventive measures tailored to mitigate the hazards and risks to which their employees are exposed. This is accomplished through the identification of workplace and occupational hazards and maintenance of a Hazard Prevention Program (HPP). The six components of an HPP required under federal OHS regulations include: an implementation plan; hazard identification and assessment methodology; conduct of hazard identification and assessment; preventive measures; employee education; and periodic OHS program reviews. The results of the hazard identification and assessment for each workplace are to be rolled up to the NPHSC to provide an overall view of the organization's highest hazards and risks, allowing for the NPHSC to participate in the development and monitoring of national-level policies, practices and procedures for the most common departmental hazards.

The audit found that very few Directors or Managers of regional programs and functions had formally assessed the hazards faced by their employees. The audit identified one example of a comprehensive hazard-specific safety manual in the Department, for the Northern Contaminated Sites program. Aside from this example, none of the regional program managers interviewed had formally identified and assessed hazards and developed and documented OHS procedures and requirements. Despite not having formal hazard-focused procedures, all managers and supervisors interviewed informally managed known hazards and promoted safety to their employees. At the time of the audit, SOHSD had a completed guide on implementing a hazard prevention program but it had not yet been rolled out widely across the Department. Without a formal hazard identification and risk assessment, it is not possible to determine if sufficient preventive and protective measures are in place to adequately mitigate existing hazards.

5.2.3 Employee OHS Training

For employees to be aware of and be able to carry out their OHS rights, duties and responsibilities, it is necessary for employers to provide all employees with general instruction and training and to ensure that their employees are trained for the specific hazards and safety requirements of their jobs. AANDC has a policy requiring that all managers and supervisors:

- Inform their employees of the potential hazards present in their respective workplaces and provide training on the safety rules and procedures applicable to these hazards; and

- Ensure that their staff receives task-specific training so that they are adequately trained and qualified to perform assigned tasks safely.

AANDC offers general OHS training, required to be taken by all employees, managers/supervisors, and OHS committee members. These training courses are administered by SOHSD and delivered by the Manager of OHS at Headquarters and by the OHS Administrative Officers in regions. This training contains relevant content and participation is tracked across the Department.

In the absence of hazard assessments and prevention programs in place, it is not possible to determine whether employees are provided with requisite training to ensure they are working in a safe manner. The audit found that there is a significant gap in the identification of hazard-specific training requirements and most employees receive very little hazard-specific training.

The audit found that new employees with responsibilities that require them to work outside of an office setting may be at elevated risk because most do not receive formal training before commencing their duties. Many research studies have highlighted that young workers within the first 6 weeks on the job are at highest risk of injury. Further, recent Canadian studies show that organizations and Provinces with strong OHS awareness and training programs aimed at young workers experience significant reductions in the frequency of injuries and fatalities.

All regions visited had up-to-date employee learning plans; however, OHS-specific training requirements were not a focus of these plans. Records of required, planned and completed OHS training were not well documented. For this reason, it was not possible to determine how much training had been carried out, or whether regional personnel had received OHS training required by law or reasonably required to ensure job safety. In addition, none of the regions examined conducted any OHS training program reviews; nor are the SOHSD or the HR Service Centres mandated to monitor or review training programs.

5.2.4 Involvement of Managers and Supervisors in the OHS program

The CLC Part II and its associated regulations include many specific employer requirements that are generally delegated to managers and supervisors. Interviews with managers and supervisors highlighted that most understand that they are responsible and accountable for OHS matters and employee safety, but are unclear about and not performing many of their OHS responsibilities. Specifically, we found that managers and supervisors generally do not:

- Conduct their own reviews and inspections of their safety programs and workplaces, including observing health and safety practices being carried out;

- Take steps to ensure compliance with OHS regulatory requirements applicable to their operations;

- Discuss OHS with employees in the context of providing performance feedback;

- Ensure that new employees receive adequate OHS training; or

- Establish budgets, set objectives, or formulate plans to address OHS needs.

5.2.5 Local Workplace OHS Committees

Local workplace OHS committees are established and generally operate in accordance with the requirements of the CLC Part II and the TB OHS Policy. The requirements to establish an OHS committee for each workplace are prescribed under Section 135.1 of the CLC Part II. The CLC Part II prescribes committee composition, methods for member appointment, and the functions and activities performed by the committee. The TB OHS Policy reiterates these legislative requirements.

We found that all regional workplace OHS committees examined have the appropriate composition and representation. Most committees demonstrated considerable advancement in the past two years since the introduction of OHS Administrative Officers in the HR Service Centres. However, opportunities for improvement do exist, as follows:

- Workplace OHS committee administration: workplace OHS committees are required to meet a minimum of nine times per calendar year and document and make available to employees the meeting minutes. They are also required to complete the form Lab 1058 – Annual Workplace Committee Report on an annual basis. The submission of the form Lab 1058 to Labour Canada, an organization within Employment and Social Development Canada, was compliant in all regions examined; however, two of the three regions examined had multiple workplace committees that struggled to meet the minimum meeting frequency requirements.

- Monthly workplace inspections: Workplace OHS committees must inspect all or part of the workplace each month. All regional workplace OHS committees examined had plans to conduct regular workplace inspections, but none met the requirement of one inspection per calendar month and two did not cover the entire workplace. For the calendar year 2013, the frequency of inspections in the regional workplace OHS committees ranged between five and nine instead of the required 12 inspections.

- Accident / incident / health hazard records: Workplace OHS committees are required to ensure that adequate records of accidents, incidents, training, and health hazards are maintained. The audit found that the form Lab 1070 – Hazardous Occurrence Investigation Report had been completed by managers/supervisors in all regions visited, with input from the workplace OHS committee. However, results of interviews indicate that there is non-reporting of incidents snd/or near misses in all regions examined. None of the workplace OHS Committees participated in the implementation and monitoring of personal protective equipment, clothing, devices or materials.

- Disposition of OHS issues: Workplace OHS committees are required to receive, consider and expeditiously resolve OHS issues brought to their attention. Committees are required to refer all unresolved issues to the NPHSC and provide management with notice of the need to resolve issues. A review of meeting minutes indicated that committees consistently took in excess of nine months to resolve OHS issues raised at meetings. In only one of the three regions visited was there a practice of notifying management of OHS issues and tracking their disposition.

5.2.6 Return to Work Program

A Return to Work Program is a proactive way for employers to help injured employees return to productive and safe work as soon as possible following an injury. The Return to Work Program defines how injury claims will be managed when employees are not able to work following a workplace injury. These programs are based on the philosophy that injured employees are often capable of safely performing productive work during the process of recovery.

AANDC's OHS Policy makes references to return to work and claims management; however, no detailed return to work procedures exists for work-related injuries. Through interviews, we observed that there is an overlap of responsibilities between the Claims Management Program and the Return to Work Program, both of which are administered by HRWSB.

The audit team reviewed seven return to work cases that involved lost time in two of the three regions examined. One region did not have any active long-standing return to work cases. There were few cases of injured workers with significant lost time, limiting our ability to assess the process of managing the return of injured employees back to full or modified duties. Notwithstanding, the audit highlighted that accountabilities for the Return to Work Program were unclear for the cases examined.

Recommendation

3. The Director General, Human Resources and Workplace Services Branch, should ensure that a program is put in place for all managers and supervisors with responsibility for employees exposed to occupational and workplace hazards receive training on developing, implementing and maintaining hazard prevention programs. Further, the DG HRWSB should perform periodic reviews of the implementation of hazard prevention programs and highlight deficiencies to departmental senior management and the National Policy Health and Safety Committee as well as to responsible Assistant Deputy Ministers and/or Regional Directors General.

Recommendation

4. The Director General, Human Resources and Workplace Services Branch, should ensure that all Assistant Deputy Ministers and internal services branch heads develop and implement hazard prevention programs for their respective areas, including formal identification and assessment of workplace hazards, formal safety training programs, and preventive and protective safety measures. Workplaces and occupations with the greatest exposure to hazards should receive immediate attention.

5.3 Occupational Health and Safety

The 2009 AANDC Audit of OHS identified the following ten recommendations:

- OHS knowledge and competency requirements for all categories of managers and employees should be defined. Appropriately detailed instructional procedures should be developed. Training and instruction standards and programs should be established and implemented using a risk-based approach (i.e. higher hazard program areas and occupations) to ensure that personnel understand and can discharge their OHS roles and responsibilities.

- Specific OHS governance requirements and procedures, applicable to Corporate and the Regions should be established for: (1) OHS objective setting, (2) development of formal plans to achieve objectives; (3) OHS auditing and evaluation; (4) OHS opinion surveys of the workforce; (5) internal reporting on the foregoing; and (6) senior management review of findings and recommendations arising therefrom. These requirements should be incorporated into the existing INAC OHS Statement of Roles and Responsibilities.

- The scope of support to be provided to internal departmental clients by SOHS Directorate and other departmental HS resources, as well as the performance standards, mechanisms for delivering such support, resource requirements for success, and procedures for monitoring delivery and impacts should be developed.

- A blueprint for future corporate OHS program development (policies, standards, and procedures), determining resource requirements, and obtaining senior management approval should be developed and implemented in consultation with the Policy HS Committee.

- An enterprise information management system requirements and procedures to support department-wide HS management and record keeping should be assessed, specified and implemented.

- Department-wide OHS programs, guidelines and procedures required for the higher risk operations carried out by departmental personnel should be identified, developed and implemented.

- Procedures to ensure proper flow of information between SOHS Directorate, HR / HS Advisors, HS Representatives, and HS Committees should be established and implemented.

- The selection and appointment of health and safety representatives at those additional locations where required should be conducted.

- The need for additional HS specialist staff, and optimal organizational placement, to adequately support the organization should be assessed.

- HRSDC approval of the existing HS committee structure, to avoid the need for creation of additional HS committees, should be obtained.

Of these 10 recommendations, six have been adequately addressed (#2, #4, #7, #8, #9 and #10) and three require continued focus to ensure that the OHS program is implemented and monitored effectively (#1, #3 and #6). One recommendation (#5) is no longer considered appropriate as it would have considerable cost implications and can be addressed through Excel-based tracking tools currently being rolled out by SOHSD.

6. Management Action Plan

| Recommendations | Management Response / Actions | Responsible Manager (Title) | Planned Implementation Date |

|---|---|---|---|

| 1. The Director General, Human Resources and Workplace Services Branch, with the support of the National Policy Health and Safety Committee, should ensure that a comprehensive National Occupational Health and Safety (OHS) Plan, based on the results of a completed departmental hazard assessment, is developed and implemented. In addition, the Senior Assistant Deputy Minister, Regional Operations, and the Assistant Deputy Minister, Northern Affairs Organization, should ensure that all regions develop and implement regional OHS plans that address national OHS priorities and that establish region-specific priorities aimed at regional hazards. | An OHS Strategic Plan was developed in 2009, in response to the 2009 OHS Audit, and includes a Hazard Prevention Program.

|

DG, HRWSB Senior ADM, Regional Operations and ADM, Northern Affairs Organisation |

June 2015 |

|

March 2016 | ||

|

September 2016 | ||

| 2. The Director General, Human Resources and Workplace Services Branch, should ensure that a departmental Occupational Health and Safety (OHS) performance dashboard that tracks progress against key performance indicators (leading and lagging) and national OHS program priorities is developed. This information should be reported to senior management and the National Policy Health and Safety Committee at regular intervals to inform their oversight of the OHS program. Further, OHS performance dashboards and region-specific program deficiencies should be reported to Regional Directors General and Workplace OHS Committees at least annually. | The current OHS tracking system will be revised to ensure that it tracks progress against key performance indicators and national OHS program priorities. Subsequently, a performance dashboard will be developed, and used as a reporting mechanism to senior management for all OHS-related activities and/or concerns. | DG, HRWSB | March 2016 |

| 3. The Director General, Human Resources and Workplace Services Branch, should ensure that a program is put in place for all managers and supervisors with responsibility for employees exposed to occupational and workplace hazards receive training on developing, implementing and maintaining hazard prevention programs. Further, the DG HRWSB should perform periodic reviews of the implementation of hazard prevention programs and highlight deficiencies to departmental senior management and the National Policy Health and Safety Committee as well as to responsible Assistant Deputy Ministers and/or Regional Directors General. |

|

DG, HRWSB | December 2015 |

|

Quarterly, as of March 2016 | ||

| 4. he Director General, Human Resources and Workplace Services Branch, should ensure that all Assistant Deputy Ministers and internal services branch heads develop and implement hazard prevention programs for their respective areas, including formal identification and assessment of workplace hazards, formal safety training programs, and preventive and protective safety measures. Workplaces and occupations with the greatest exposure to hazards should receive immediate attention. |

|

DG, HRWSB | May 2015 |

|

December 2015 |

Appendix A: Audit Criteria

To ensure an appropriate level of assurance to meet the audit objective, the following audit criteria were developed, in alignment with the requirements of the Canada Labour Code, Part II and its associated regulations:

Audit Criteria and Control Objectives

Commitment, Leadership and Participation

1. Senior management provides leadership for occupational health and safety (OHS) activities and assumes overall responsibility for the OHS program.

1.1 Senior management provides appropriate financial, human, and organizational resources to plan, implement, check, review, and correct the OHS program.

1.2 Senior management reviews the organization's OHS program at planned intervals.

1.3 Senior management actively promotes the OHS program.

2. Roles, responsibilities, and authority with respect to the maintenance and review of the OHS program are established and communicated.

2.1 Senior management has defined roles, assigned responsibilities, established accountability, and delegated authority to implement an effective OHS Program.

3. Departmental OHS objectives and policies are established and are appropriate to meet the organizations OHS needs.

3.1 Senior management has established and implemented an OHS policy and measurable objectives.

3.2 Senior management encourages active participation on the part of workers and worker representatives in the establishment and maintenance of the OHS Program.

OHS Planning and Implementation

4. Hazards and risks are identified and assessed on an ongoing basis and results of this process are used to set objectives and targets and to develop preventive and protective measures.

4.1 The organization has established and maintains a process to identify and assess hazards and risks on an ongoing basis.

4.2 The hazard assessment is used to set objectives and targets and to develop preventive/protective measures including leveraging best practice across regions.

4.3 Employees are proactively consulted by OHS specialists and management in needs identification, program implementation and problem solving.

5. OHS plans and performance expectations are clearly established, communicated and performance is monitored.

5.1 The organization has documented OHS objectives and targets for relevant functions and levels within the organization.

5.2 Objectives and targets are established based on identified hazards and risks.

5.3 The organization established and maintains plans for achieving its objectives/targets.

5.4 A plan to guide implementation of the OHS Framework has been developed and communicated to senior management, and is achievable within allotted resources.

5.5 Where additional resources are required to implement the framework, these allocations are approved by Senior Management.

6. Appropriate OHS training activities are established and delivered to ensure that workers are competent to carry out their duties and responsibilities in a safe manner and are aware of OHS requirements, rights and responsibilities.

6.1 OHS skills and knowledge requirements have been identified for all occupations and work activities and reflect hazards identified in the hazard assessment.

6.2 OHS training programs have been developed for instructing employees and contractors based on duties and responsibilities.

6.3 Mechanisms exist to verify OHS-related competency of employees and provide timely refresher sessions.

6.4 Appropriate training records are maintained and processes exist to ensure that employees receive any information, instruction and training necessary to possess the required competencies.

7. A return to work programs is in place to transition injured workers back to duties or temporary work assignments in response to work related illnesses or injuries.

7.1 A return to work program has been developed and communicated to all managers, whether this be centralized or within each Department or Branch.

7.2 Managers and employees understand and support employer obligations for providing suitable employment for employees returning to work.

7.3 Senior management supports and actively promotes the Return to Work program.

8. Committees are established and operate per requirements of Canada Labour Code Part II and regulatory and policy requirements.

8.1 Minutes of workplace OHS Committee meetings are maintained as prescribed by law and policy.

8.2 Annual reports of workplace OHS Committee are prepared and submitted for each committee as prescribed by law and policy.

8.3 The workplace OHS Committee expeditiously disposes of matters raised concerning health and safety.

8.4 Membership of the workplace OHS Committee conforms to the requirements of the CLC-II.

8.5 Records of complaints and investigations are maintained by the workplace OHS Committee in accordance with CLC-II.

9. Adequate procedures for investigations and responses to hazardous occurrences, including near misses, are established and carried out.

9.1 The organization has established and maintains procedures to monitor, measure, and record OHS performance and the effectiveness of the OHS Program on a regular basis.

9.2 Performance monitoring and measurement:

- Determines the extent to which the OHS policy, objectives, and targets are being met;

- Provides feedback on OHS performance;

- Determines whether the day-to-day arrangements for hazard and risk identification, assessment and elimination or control are in place and operating effectively;

- Provides the basis for decisions about improvements to hazard and risk identification, assessment, elimination/control, and to the OHS Program.

Monitoring and Oversight

10. Every part of the work place is inspected at least once each year by the Workplace Committee or OHS Representative.

10.1 Procedures have been developed for conducting workplace inspections and include the development of annual inspection plans (focus on all areas of the workplace, with concentration on greatest hazards and risks).

10.2 An inspection schedule has been developed to identify inspectors and frequency of inspections required by each inspector.

10.3 Managers and Supervisors perform periodic inspections to identify hazards and risks, for purposes of compliance assurance and implementation of preventive and protective measures.

10.4 Inspection reports are prepared for all inspections and results of inspections are properly documented.

10.5 Compliance with the inspection schedule is monitored to ensure all planned inspections are performed as scheduled.

11. Senior management reviews the organization's OHS program at planned intervals to ensure its continuing suitability, adequacy, and effectiveness.

11.1 Management and Safety Consultants monitor the status of completion of the hazard assessments and hazard prevention programs.

11.2 Senior management reviews the organization's OHS Program at planned intervals to ensure its continuing suitability, adequacy, and effectiveness.

11.3 An audit process for the OHS Program is in place.

Appendix B: Relevant Policies/Directives/Legislation/Authoritative Sources

The following policies, directives, legislation and authoritative sources were consulted as part of this audit:

- Canada Labour Code, Part II

- Canada Occupational Health and Safety Regulations

- Treasury Board Policy on Safety and Health

- Criminal Code of Canada

- Safety and Health Committees and Representative Regulations

- Treasury Board and National Joint Council Directive on Occupational Health and Safety

- AANDC OHS Program Manual (includes AANDC OHS policies and procedures)

- Canadian Safety Association’s Standard CSA Z1000 – Occupational Health and Safety Management Systems